| Photo of the month – October 2024 |

Some of it’s fine, but some of it’s not!

And we could also say: Small cause, big effect … but see for yourself:

When there’s such a big bulge in a trailer, you don’t have to be a gifted clairvoyant to guess that the load has probably moved well away from its original, intended position.

Figure 1 [Max Reich]

Figure 2 shows us what we want to see. The load consists of wire rod coils. The problems with this load can be stated in just a few words. Heavy, round and, when standing on their sides, able to roll in the direction of travel. This would be a challenging task for anyone involved in the business of loading and securing cargo.

Figure 2 [Max Reich]

However, we want to start by showing you where the load is pressing against the tarpaulin.

Figure 3 [Max Reich]

We have no idea why the load has tipped over. Maybe a brake maneuver, a right-hand bend, or perhaps both. Or did the load just “slip away” during the journey.

As a lot was done right when this load was secured, let’s start by looking at the other cargo elements that are still “standing”.

Figure 4 [Max Reich]

At first glance, we were very impressed because we have rarely seen such good load securing. We estimate the weight of this load of wire rod coils to be approximately 3 tonnes. On the loading surface, we see lateral wooden beams lying on anti-slip material. We were unable to detect any anti-slip material between the lumber and the coils. That's a pity! The coils were bundled with a belt at approximately 10 o’clock and 2.30. That’s a very good idea that makes the coils more resistant to tipping. They were secured to both the front and back with a loop lashing. That, too, is a very good and reliable mode of securing. The coils were secured at the top with two loop lashings to prevent them from tipping. We won’t reward this idea with an “A” but only with a “B”, because the coils were able to slip against the sheeting if subjected to a load. In such a case, we would have incorporated a round turn in the loop lashing around the coil. Although this means that the pretensioning is not as well distributed, the twist makes it difficult or even impossible for the belts to slip.

So what went wrong with these load securing measures and allowed the coils to tip over into the tarpaulin, as can be seen in Figure 3?

The coils were able to slip away at the bottom. They were restrained well at the top but were able to slip on the sheeting and lumber at the bottom. That was the problem. If we take a closer look at the lumber, we can see indentations that are probably due to other loads of wire rod coils. You could almost say that that is a bit like a tight fit. However, it is only partial and also completely random, meaning that it is useless for securing purposes.

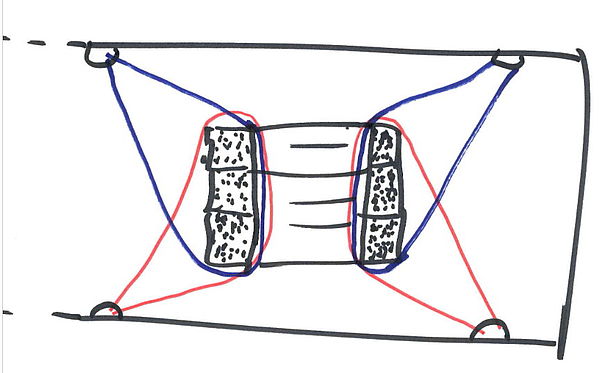

How might this problem be overcome? Relatively simply:

- We release the direct lashings in the bottom area and guide the ends back to the same side When doing this, we make sure that the longitudinal component is larger than the transverse component. What that means is that the loop lashings perform two tasks and secure the load both to the side and against forward or backward movement.

- Now we just need two more belts so that we can also attach these loop lashings on the opposite side. These direct lashings now have two functions:

- On the one hand, they act against forward movement.

- And, on the other, they prevent the coils from slipping away at the base.

- However, because the loop lashing is only attached and effective on one side, it needs a counterpart on the other side.

- To make sure that the coils are held absolutely securely, we would change the front direct lashings in the bottom area in the same way (hence the two additional belts).

- The result is that the coils now have a secure support at the bottom and are no longer able to slip away;

Diagram 1 [GDV]

Conclusion:

The load in this example was secured very well but, unfortunately, the arrangements were not thought through to the end. This month, we won’t dwell on the fact that one or two of the belts were ready for scrapping.

Your load securing columnists wish you a safe autumn!

Back to beginning