| Photo of the month – September 2024 |

[German version] |

The Münchhausen School of load securing

In his tales, the good old Baron Marco von Münchhausen tells how he pulled himself out of the mire by his own hair. In doing so, he also saved the life of his horse. A splendid fellow, old Münchhausen. Transposed to modern technical debates that struggle with the impossibility of practical implementation, his place would probably be taken by the legendary Siemens skyhooks.

But let's start at the beginning:

The load being transported in this Photo of the Month is wood shredding residue. This takes the form of a pulped timber substance extracted by means of a screening process (the coarse matter, the overflow from a rotary sieve). All in all, typical bulk material which you would expect to be transported in skip containers or high-volume vehicles of the sort used for woodchips, for example. Nothing of the sort! Here, we have an example in which a curtainsider trailer has been transformed into an “all-singing, all-dancing jack of all trades”.

Figure 1 [Raymond Lausberg]

In Figure 1, we can see just such a vehicle. It is listing to starboard (tilting a little to the right in the direction of travel), clearly showing that the loose load has shifted a bit.

Figures 2 and 3 [Raymond Lausberg]

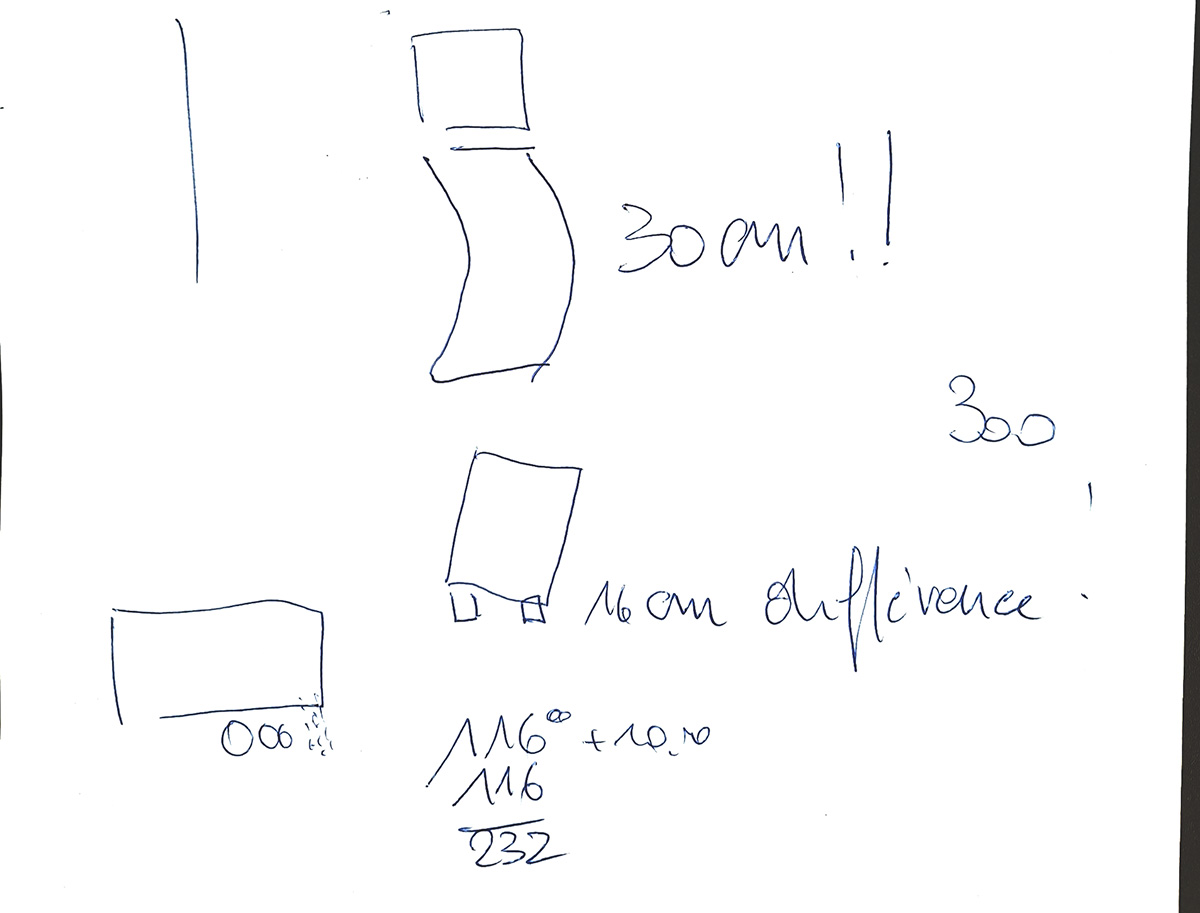

Even if the base on which the vehicle is standing has not been calibrated to the nearest centimeter, the differences in the measurements show a considerable imbalance. That’s not the right way to go about things!

Figure 4 [Raymond Lausberg]

Diagram 1 [Raymond Lausberg]

Not only was the vehicle tilting to the side, it was also bulging outwards due to the lateral shift in the load. According to the measurements made by the recording police officer, it had been widened by 30 cm on one side. In addition to all this, we wouldn’t want to forget to mention that the vehicle and its tarpaulin were in a lamentable condition. The tarpaulin looked more like a patchwork quilt than a vehicle element intended to make a large contribution towards securing the load

Figure 5 [Raymond Lausberg]

Which brings us back to our main topic – load securing. Figure 5 shows that some six or so square metal plates had been set into the tarpaulin on both sides and were attached to one another horizontally by means of belts. This shows that the responsible parties were aware of the lack of adequate securing and had therefore attached the right and left sides to try to improve the arrangements. We admit that the comparison with Münchhausen is perhaps not quite right, but attaching one piece of poor load securing to the next piece of poor load securing does not produce good load securing, as the photos above clearly show. The icing on the cake is the fact that a specialist company actually certified this “securing” arrangement. The proof of this “Münchhausenesque load securing” can be clearly seen in the photos.

So why didn’t it work?

Since we don’t know the weight of the load, we cannot say with certainty whether the tarpaulin provides a sufficient level of load securing.

What is certain, however, is that this strange idea of attaching the two sides of the tarpaulin to one another was primarily intended to stop the vehicle from bulging during the journey.

We think that this sounds very much like one of Münchhausen’s tales. This bulk material does not have any defined friction in the same way as a normal load resting on a pallet, for example. It has no inner stability and so it moves a little like a blancmange on the loading surface and needs to be properly restrained by solid walls at the sides of the vehicle. Why neither the inventor of this Münchhausenesque load securing nor the specialist load securing company (which obviously considered itself to be above such things) had the idea of attaching the square metal plates to the loading surface using belts fastened crosswise is a mystery to us, because if they had done so then the load would have been secured to the side and the arrangements would not have been purely cosmetic. The answer is probably that crosswise belts would have interfered with loading and unloading, but the arrangements as they are were simply not good enough!

The manufacturer would undoubtedly have immediately revoked this vehicle’s XL certificate if it had heard that the vehicle had been modified in this way. We have never heard of a certificate that

- permitted the loading of loose bulk cargo, or

- recommended reinforcing the external tarpaulin with metal plates and belts, and

- authorized the widening of the vehicle by the load.

Not even testing organizations are authorized to issue certificates that permit the vehicle to be widened beyond the legally approved dimensions due to the tarpaulin bulging during the journey.

We all agree that loads such as this belong in trailers designed for bulk cargoes. Such solutions are also equipped with transport systems such as moving floors, for example, which greatly simplify unloading.

Figure 6 [Raymond Lausberg]

We want to make one final comment, this time concerning the weight of the vehicle. The dents in the tarpaulin show how flexible and possibly also over-height the vehicle was. Because this was the case, we suspect that the roof on the left-hand side of the vehicle was lashed down with three belts, which undoubtedly had their counterparts on the right-hand side.

Figure 7 [Raymond Lausberg]

And finally, we wouldn’t want to deprive you of the opportunity to see this photo. This belt was being used in all seriousness, and probably had been for many months, if not years. It had always been subjected to high stresses at the same point and, just like the tarpaulin, had ceased to be fit for purpose a long, long time ago. To see a vehicle in this sort of condition speaks volumes about its owner’s attitude to safety-related parts and accessories. Here, the desire to optimize cost-effectiveness not only outstripped considerations of safety but reduced them to an absurdity. What a shame that there are no separate legal provisions that make such reckless behavior punishable by law.

Your load securing experts wish you a warm and sunny late summer.

Back to beginning